Product Introduction:

Drilling is a cutting process that uses a drill bit to cut a hole of circular cross-section in solid materials. The drill bit is usually a rotary cutting tool, often multi-point. The bit is pressed against the work-piece and rotated at rates from hundreds to thousands of revolutions per minute. This forces the cutting edge against the work-piece, cutting off chips from the hole as it is drilled. Normally, the drilling process carries out late, and it is a crucial operation that can bring essential consequences if the tool malfunctions or is run beyond its capacity. There are three major shapes of the cutting edges: conical, dual face, candler. The feature of conical shape is the flank face is conical and the clearance angle increases toward the center of drill. It has wide applications, commonly used for both soft and hard materials. Our SC series will be a great selection for machining of cast iron, silicon-aluminum alloy

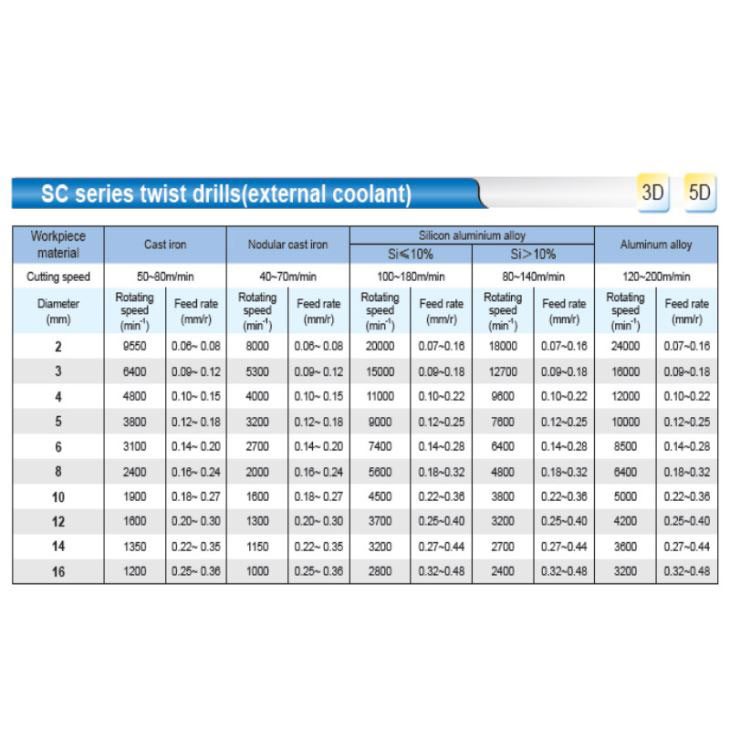

Cutting Parameters:

| Work Piece Material | Silicon Aluminum Alloy | |||

| Cutting Speed | 100 – 180m/Min | 80 – 140m/Mim | ||

| Diameter | Rotating Speed | Feed Rate | Rotating Speed | Feed Rate |

| 2 | 20000 | 0.07-0.16 | 18000 | 0.07-0.16 |

| 3 | 15000 | 0.09-0.18 | 12700 | 0.09-0.18 |

| 4 | 11000 | 0.10-0.22 | 9600 | 0.10-0.22 |

| 5 | 9000 | 0.12-0.25 | 7600 | 0.12-0.25 |

| 6 | 7400 | 0.14-0.28 | 6400 | 0.14-0.28 |

| 8 | 5600 | 0.18-0.32 | 4800 | 0.18-0.32 |

| 10 | 4500 | 0.22-0.36 | 3800 | 0.22-0.36 |

| 12 | 3700 | 0.25-0.40 | 3200 | 0.25-0.40 |

| 14 | 3200 | 0.27-0.44 | 2700 | 0.27-0.44 |

| 16 | 2800 | 0.32-0.48 | 2400 | 0.32-0.48 |

Application guide of drills:

1. Guarantee tight clamping by using thrust bearing type collet chuck.

2. Ensure the size of clamping length is over 1.5times of drill diameter.

3. The radial run-out should be under 0.02mm.

4. Do not clamp on the drill flutes.

5. The coolant liquid should be injected to the end and the middle.

6. Reduce the feed rate when drilling interrupted part.

7. When machining step holes, divided the process to two drilling stage. Drill the larger diameter hole first.