Product Introduction:

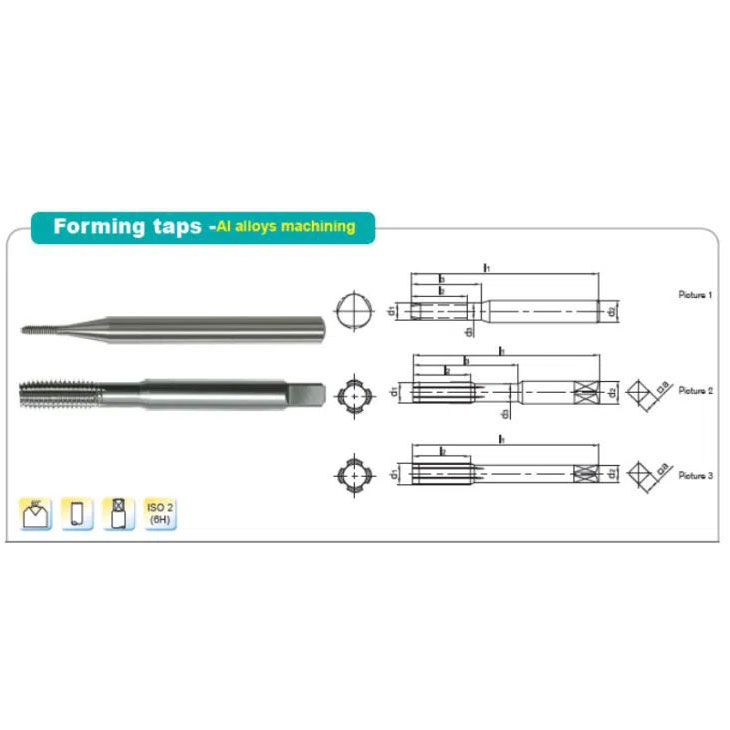

Nowadays, the cutting tools contribute the majority of the produced threads in all types of manufacturing industries. The internal threads were created by cutting taps. These are tools that are designed to remove material from the hole leaving a finished internal thread form in the geometry intended. Forming taps create thread by displacement of material within the hole. The formed material assumes the shape of the thread form of the tap without the creation of chips. Flutes are replaced by lubrication grooves to provide some relief from the friction created during the process. By using our form tap, it will help you to achieve a smooth and burnished surface finish.

Threading cutter code key

4201ACS-M5x0.5-6H

“4” = threading cutter

“2” = square straight shank

“0” = cutting taps

“1” = Right-hand flute

“A” = Aluminum alloy

“C” = internal coolant

“S” = blind-hole machining

“-M5x0.5” = nominal diameter of

threading and pitch

“6H” = ISO metric thread

Cutting Parameters:

| Work Piece Material | Cutting Speed(M/Min) |

| Stainless Steel/Mild Steel | 5-20 |

| Aluminum Alloy | 20-50 |

| Cast Aluminum Alloy | 15-40 |

The tool entering feed is less than 70% of threading feed. It is in direct proportion to the diameter of the tap. The above cut parameters are suitable for thread cutters with helical flute. Please reduce feed rate and cutting speed by 20% to 40% if it is straight-flute tools.