Product Introduction:

This kind of Lathe Tool is suitable for carbon steel, alloy steel, non-ferrous metal, etc. It has high strength, long service life, fast cutting speed, stable size and clear grain. When the thread is machined, the chips are discharged forward, so there is no need to worry about the damage of the chips to the tool and the internal thread. The core size of the Lathe Tool is relatively large, and has strong strength, thus it can withstand large cutting forces. What’s more, it has the advantages of simple structure, high hardness wear resistance as well as long service life. It can be operated manually or on a machine tool, and it is widely used in production. The Lathe Tool also can be customized according to the requirements of different customers. It wins a good reputation among the clients due to high quality.

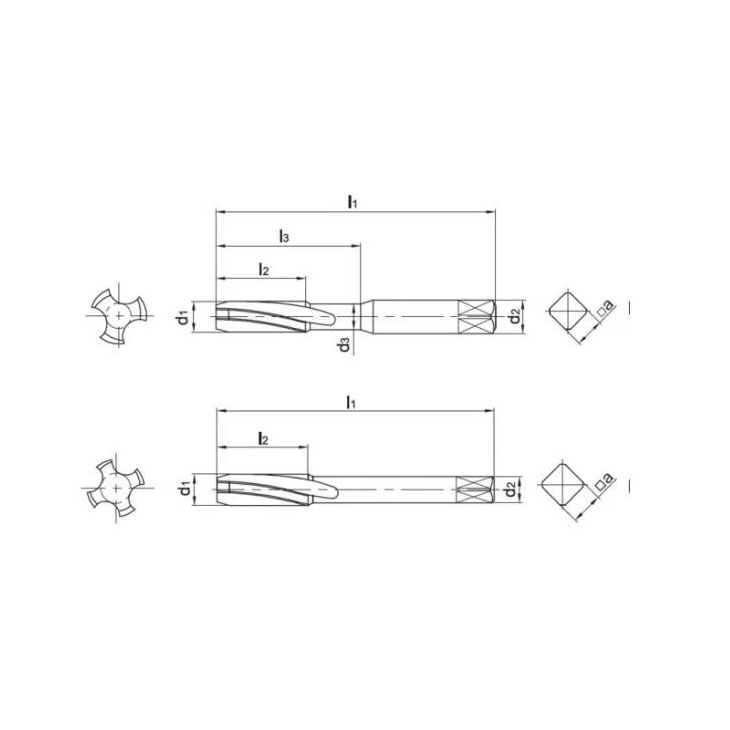

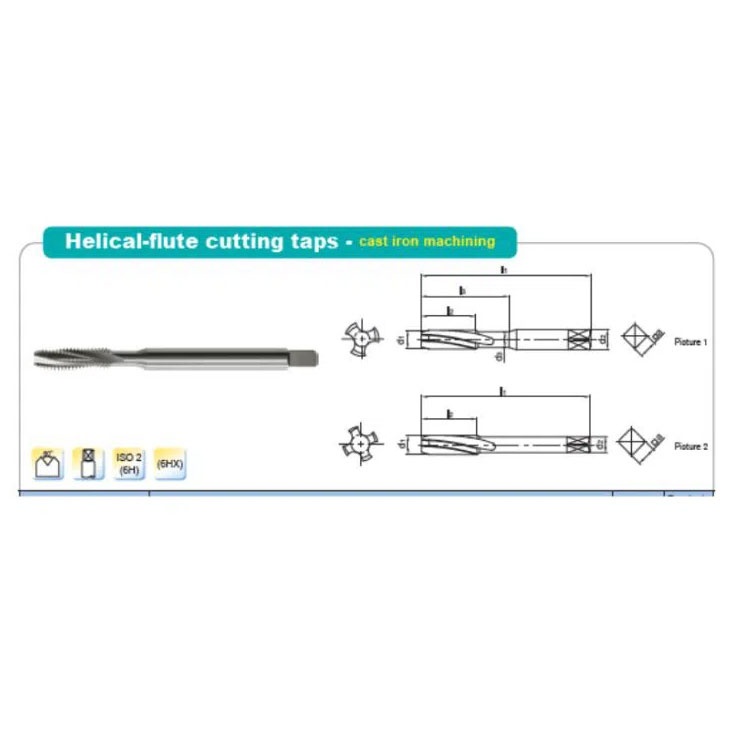

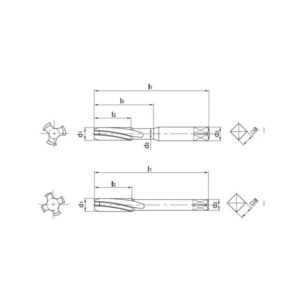

Model name: 4201C helical cutting tap

Structure: Right-hand twist

Application: Cast iron

Payment method: T/T

Place of Origin: China

Process of tapping and tapping torques:

1. While it begins to machine, cutting chamfer will get into the work piece gradually. In addition, machined torques appears to be increased by linear.

2. Cutting (forming) chamfer participates in machining process. Meanwhile, the tooth of correction plays a role in correcting and directing. Also, torques is gradually reached at a peak at that time.

3. When tapping nearly close to the bottom, spindle speed and feed rate are decreasing synchronized until to zero.

4. Spindle starts reversal, round speed and feed rate are both increase gradually.

5. Adjusting tooth seceded gradually.

6. Once the tap entirely seceded, tapping process is over.

Thread overlap ratio:

The thread overlap ratio is the ratio of effective chimeric height of external thread and internal thread and the height of standard tooth. It must be considered before machining of internal thread pre-hole.