Product Introduction:

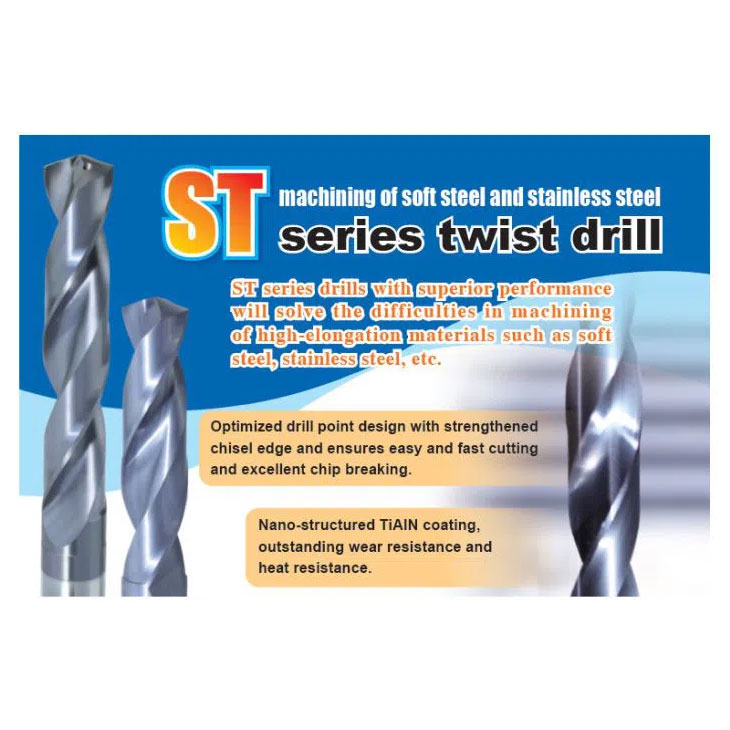

This Metal Drill Bit for Steel is one of the best sellers for machining of soft steel and stainless steel. It has superior performance, can solve the difficulties in machining of high-elongation materials such as soft steel, stainless steel, etc. The optimized drill point design with strengthened chisel edge and ensures easy and fast cutting, and excellent chip breaking. In addition, our Metal Drill Bit for Steel has outstanding wear resistance and heat resistance. This product can be supplied in different specification to meet different requirements. Please check the details carefully and let us know your requirements before purchasing!

Advantages

The Metal Drill Bit for Steel is economical and can be universally applied. This product can give a long service with very low maintenance cost. Every details reflect our exquisite workmanship. We can provide you with this product in a large quantity at wholesales price. And if you buy our products, we will give you our best after-sales service!

Cutting Parameters:

| Work Piece Material | Silicon Aluminum Alloy | |||

| Cutting Speed | 100 – 180m/Min | 80 – 140m/Mim | ||

| Diameter | Rotating Speed | Feed Rate | Rotating Speed | Feed Rate |

| 2 | 20000 | 0.07-0.16 | 18000 | 0.07-0.16 |

| 3 | 15000 | 0.09-0.18 | 12700 | 0.09-0.18 |

| 4 | 11000 | 0.10-0.22 | 9600 | 0.10-0.22 |

| 5 | 9000 | 0.12-0.25 | 7600 | 0.12-0.25 |

| 6 | 7400 | 0.14-0.28 | 6400 | 0.14-0.28 |

| 8 | 5600 | 0.18-0.32 | 4800 | 0.18-0.32 |

| 10 | 4500 | 0.22-0.36 | 3800 | 0.22-0.36 |

| 12 | 3700 | 0.25-0.40 | 3200 | 0.25-0.40 |

| 14 | 3200 | 0.27-0.44 | 2700 | 0.27-0.44 |

| 16 | 2800 | 0.32-0.48 | 2400 | 0.32-0.48 |

Grade Information:

KDG3013: New AlCrN substrate composite coating, with excellent abrasion resistance and bonding resistance, improves the stability of the insert edge. Unique coating after-treatment technology effectively reduces the cutting resistance for smoother chip evacuation and higher security.

KDG303:

Ultra-fine carbide substrate with high strength, toughness and wear resistance, in combination with nano-structured nc-TiAlN coating aiming at optimizing drilling operations, makes sure the tools have very high toughness and hardness. Unique coating technology gives the tools smooth surface and excellent wear resistance, and outstanding thermal stability and chemical stability provide effective protection for the cutting edge.