Product Introduction:

The 1101SC05 series is well designed for materials with short chips such as cast iron, silicon-aluminum alloy, etc. The cutting edge and shank have the same diameter will ensure the cutting performance and efficiency. Generally speaking, the small point angle is suitable for soft easy-to-cut material and large angle for hard materials or high-efficiency machining. Moreover, the core is an important factor that influence the rigidity and chip control of a drill. The thin core will lead to low axial cutting force, low rigidity which will be a good choice for easy to cut materials. On the contrary, the thick core will requires large axial cutting for and high rigidity which will be a better choice for machining of high hardness materials, cross hole drilling, etc. In order to decrease the friction with inside wall of the drilled hole, there is a slight back taper from tool nose to shank. The degree is usually represented by the quantity decreasing in the diameter per 100 mm flute length.

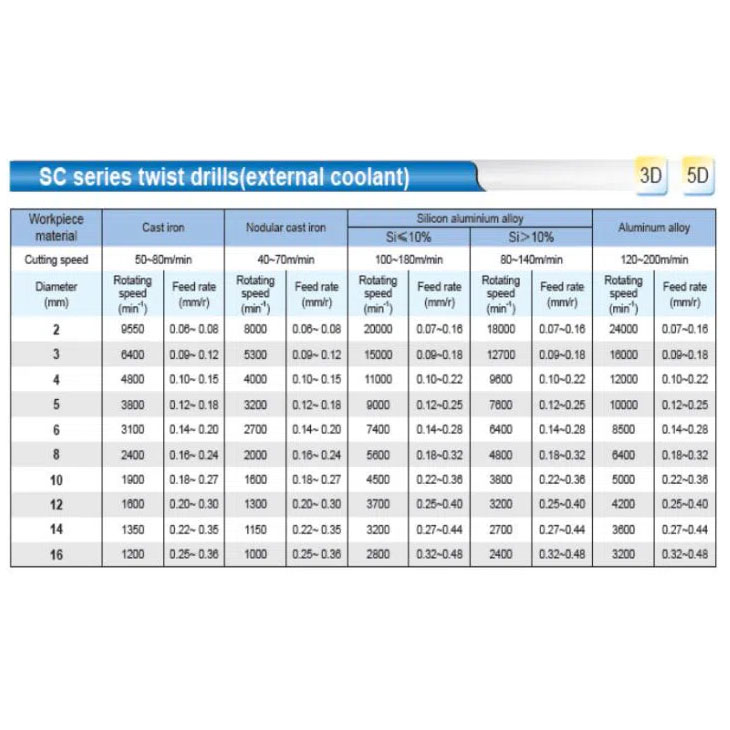

Cutting Parameters:

| Workpiece Material |

Cast Iron | Silicon Aluminum Alloy | Aluminum Alloy | |||||

| Si≤10% | Si>10% | |||||||

| Cutting Speed | 50~80m/Min | 100~180m/Min | 80~140m/Min | 120~200m/Min | ||||

| Diameter(Mm) | Rotating Speed |

Feed Rate | Rotating Speed |

Feed Rate | Rotating Speed |

Feed Rate | Rotating Speed |

Feed Rate |

| 2 | 9550 | 0.06~ 0.08 | 20000 | 0.07~0.16 | 18000 | 0.07~0.16 | 24000 | 0.07~0.16 |

| 3 | 6400 | 0.09~ 0.12 | 15000 | 0.09~0.18 | 12700 | 0.09~0.18 | 16000 | 0.09~0.18 |

| 4 | 4800 | 0.10~ 0.15 | 11000 | 0.10~0.22 | 9600 | 0.10~0.22 | 12000 | 0.10~0.22 |

| 5 | 3800 | 0.12~ 0.18 | 9000 | 0.12~0.25 | 7600 | 0.12~0.25 | 10000 | 0.12~0.25 |

| 6 | 3100 | 0.14~ 0.20 | 7400 | 0.14~0.28 | 6400 | 0.14~0.28 | 8500 | 0.14~0.28 |

| 8 | 2400 | 0.16~ 0.24 | 5600 | 0.18~0.32 | 4800 | 0.18~0.32 | 6400 | 0.18~0.32 |

| 10 | 1900 | 0.18~ 0.27 | 4500 | 0.22~0.36 | 3800 | 0.22~0.36 | 5000 | 0.22~0.36 |

| 12 | 1600 | 0.20~ 0.30 | 3700 | 0.25~0.40 | 3200 | 0.25~0.40 | 4200 | 0.25~0.40 |

| 14 | 1350 | 0.22~ 0.35 | 3200 | 0.27~0.44 | 2700 | 0.27~0.44 | 3600 | 0.27~0.44 |

| 16 | 1200 | 0.25~ 0.36 | 2800 | 0.32~0.48 | 2400 | 0.32~0.48 | 3200 | 0.32~0.48 |