Product Introduction:

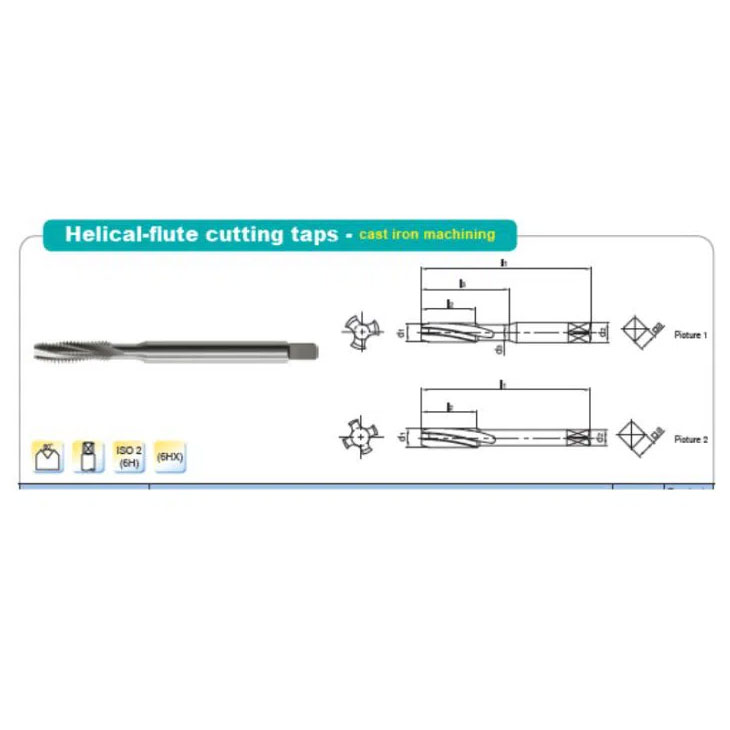

Comparing with form tapping, the cutting taps are more flexible. As long as the geometry of the cutting taps can be altered to match the characteristics of the materials being tapped, the cutting taps can be used in various applications. They are not limited to the materials like form tapping. The form tapping can only used for machining of soft materials, like aluminum alloy. But the cutting taps can easily handle the machining of cast iron. Moreover, cutting taps require less machine power than form taps, a major consideration as tap diameter increases. Our spiral flute tap s applying the ideal flute shape and well-designed helix angle which will be extremely helpful for the smooth of chips removal.

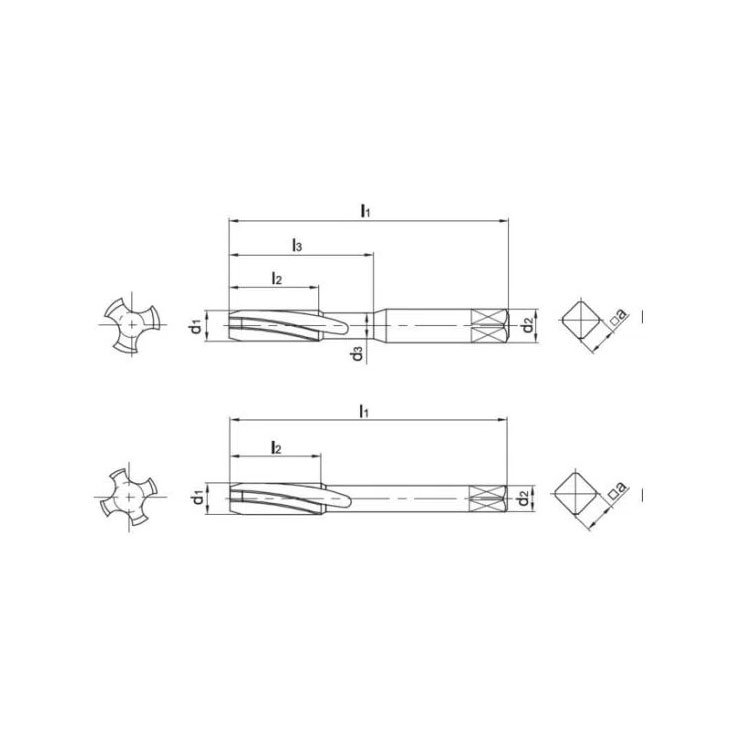

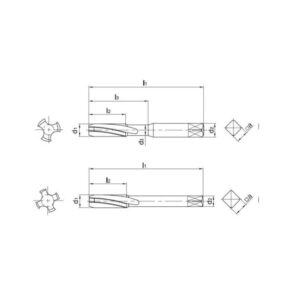

| Type | Length Of Cutting Tap | D1 | P | D2 | D3 | L1 | L2 | L3 | Number Of Teeth |

| 4201C-M3*0.5-6H | 3P | M3 | 0.5 | 3.5 | 2.3 | 56 | 11 | 18 | 3 |

| 4201C-M4*0.7-6H | 3P | M4 | 0.7 | 4.5 | 3.1 | 63 | 13 | 21 | 3 |

| 4201C-M5*0.8-6H | 3P | M5 | 0.8 | 6 | 4 | 70 | 16 | 25 | 3 |

| 4201C-M6*0.75-6H | 3P | M6 | 0.75 | 6 | 5 | 80 | 19 | 30 | 3 |

| 4201C-M6*1-6H | 3P | M6 | 1 | 6 | 4.7 | 80 | 19 | 30 | 3 |

| 4201C-M7*1-6H | 3P | M7 | 1 | 7 | 5.7 | 80 | 19 | 30 | 3 |

| 4201C-M10*1-6H | 3P | M10 | 1 | 10 | 8.7 | 100 | 20 | 39 | 4 |

Application Case:

Work piece: Auto engine shell

Material: Al alloy (HB90-120)

Tool type: 4222ACS-M10*1.25-6H

Cutting parameters: N=1300r/min, F=1625mm/min, H=29mm

Machining tool: Horizontal machining center

Cooling style: Emulsified liquid cooling.