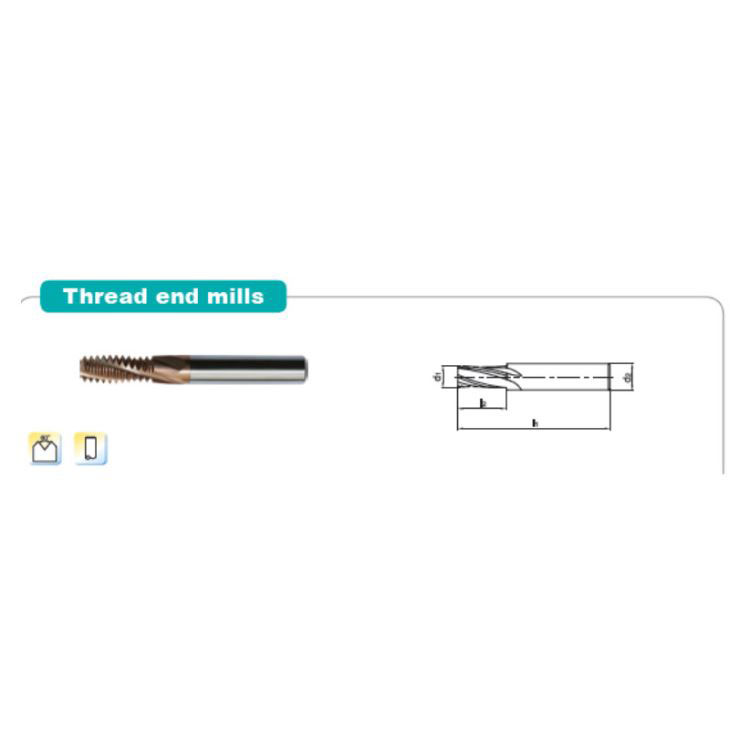

Product Introduction:

Thread milling is composed of tool rotation and helical interpolate mill of machine tool. In a circle interpolation process, required threads are machined by using the geometry shape of tool and moving axially with a pitch. Thread milling can use arc entering method and radial entering method. Arc entering: placidly entering and out leads to almost no cutting traces or vibration, so that it is particularly suitable for materials difficult to be machined and precise threading. The 4111 series combines with the new technology grade of KTG4015 will be the powerful tools for machining of carbon steel and alloy steel.

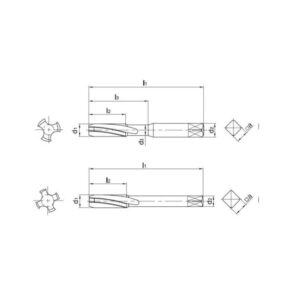

| Type | D | D1 | P | D2 | L1 | L2 | Teeth | Grade | Pre-Hole Diameter |

| 4111-M3*0.5 | M3 | 2.35 | 0.5 | 4 | 50 | 6 | 3 | KTG4015 | 2.5 |

| 4111-M4*0.7 | M4 | 3.15 | 0.7 | 4 | 50 | 8 | 3 | KTG4015 | 3.3 |

| 4111-M5*0.5 | M5 | 4.3 | 0.5 | 6 | 50 | 10 | 3 | KTG4015 | 4.5 |

| 4111-M5*0.8 | M5 | 4 | 0.8 | 6 | 50 | 10 | 3 | KTG4015 | 4.2 |

| 4111-M6*0.75 | M6 | 5 | 0.75 | 6 | 60 | 12 | 4 | KTG4015 | 5.25 |

| 4111-M6*1 | M6 | 4.75 | 1 | 6 | 60 | 12 | 4 | KTG4015 | 5 |

| 4111-M8*1 | M8 | 6.65 | 1 | 8 | 60 | 16 | 4 | KTG4015 | 7 |

| 4111-M8*1.25 | M8 | 6.45 | 1.25 | 8 | 60 | 16 | 4 | KTG4015 | 6.75 |

| 4111-M10*1 | M10 | 8.55 | 1 | 10 | 75 | 20 | 4 | KTG4015 | 9 |

| 4111-M10*1.5 | M10 | 8.1 | 1.5 | 10 | 75 | 20 | 4 | KTG4015 | 8.5 |

| 4111-M12*1.25 | M12 | 10.25 | 1.25 | 12 | 75 | 24 | 4 | KTG4015 | 10.75 |

| 4111-M12*1.75 | M12 | 9.75 | 1.75 | 12 | 75 | 24 | 4 | KTG4015 | 10.25 |

| 4111-M14*1 | M14 | 12.35 | 1 | 14 | 75 | 20 | 4 | KTG4015 | 13 |

| 4111-M14*1.5 | M14 | 11.9 | 1.5 | 14 | 75 | 28 | 4 | KTG4015 | 12.5 |

| 4111-M14*2 | M14 | 11.4 | 2 | 14 | 75 | 28 | 4 | KTG4015 | 12 |

| 4111-M16*2 | M16 | 13.3 | 2 | 16 | 90 | 32 | 6 | KTG4015 | 14 |

| 4111-M18*1 | M18 | 16.15 | 1 | 18 | 90 | 20 | 6 | KTG4015 | 17 |

| 4111-M18*2.5 | M18 | 14.75 | 2.5 | 18 | 90 | 36 | 6 | KTG4015 | 15.5 |

| 4111-M20*2 | M20 | 17.1 | 2 | 18 | 100 | 40 | 6 | KTG4015 | 18 |

| 4111-M20*2.5 | M20 | 16.65 | 2.5 | 18 | 100 | 40 | 6 | KTG4015 | 17.5 |

The solutions of common problems in thread milling

| Common Problems | Reasons | Solutions |

| Roughness On Internal Thread Milling Cutter Surface | Too Long Overhang | Decrease The Length Of Overhang |

| Select Wrong Type | Select Appropriate Tool(E.G. Tool With Helix Flute) | |

| Poor Chip Removal | Select Helix Flute Tap; Adopt Inner Cooling | |

| Too Large Cutting Force | Decrease Cutting Force | |

| Unreasonable Cutting Parameter | Adjust Cutting Parameter | |

| Severe Tool Wear | Unreasonable Machining Mode | Adopt Down Milling; Adopt Arc Cut-In Milling. |

| Uncoated Tools/Inappropriate Coated | Adopt Coated Tool/ Instead Coat | |

| Too Large Overhang | Decrease Length Of Overhang |