-

AL Super Bright Aluminum Processing Series

- Suitable for high efficient and super bright processing of aluminum alloy materials.

- Variable helix angle and differential flute pitch, reduces and eliminates vibration High precision of machine surface.

- Special edge design, Effectively solve the problem of sticking.

-

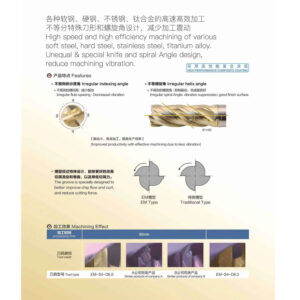

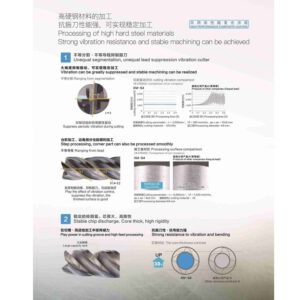

EM High Performance

- Suitable for high hardness steel, high efficiency processing.

- Unequal spiral Angle, unequal pitch design, has excellent vibration resistance.

- Suitable for high efficiency cutting with large cutting depth and width (good rigidity of machine tool)

- Unequal helical Angle, excellent vibration resistance.

-

EMR Endmills for Roughing Application

- Suitable for roughing of steels & cast iron.

- Special cutting edge chip breaker treatment,

- Suitable for rough machining of groove and side wall of workpiece.

- TiSiN coating.

- Improve cutting edge wear resistance and tool rigidity.

-

-

MM Suitable for Micro Diameter Pocket Milling

- Suitable for deep groove processing various steel and cast iron.

- High performance TiSiN coating for high temperature and wear resistance.

- Long neck design avoid collisions with workplace, Suitable for deep pocket milling Of mold rib.

- Fine grinding, high precise sizes.

-

Parallel Shank Twist Drills

(Jobber, Long, Extra Long, Stub, Step Drills, Sub Land Drills and Core Drills)

-

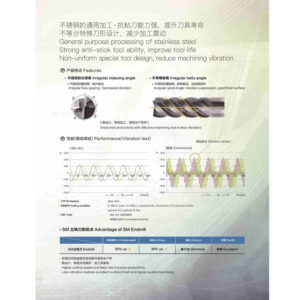

SM Stainless Steel General Processing End Mill

- Suitable for general processing of stainless steel.

- Special cutting edge design, Effectively solve the problem of cutting edge chip Sticking

- Stainless steel special coating, cutting smooth, anti-stick tool ability, improve tool Life.

- Unequal special knife shape, reduce vibration, high surface finish.

-

-

Spiral Flute Reamer

Product Name: Spiral fluted reamer

Model name: 3101H7 and 3103H7

Drill diameter range: 4.0mm to 20.0mm

Material: Tungsten carbide

Flute type: Right or Left helical flute

Brand name: ZCC·CT -

Straight Flute Reamer

Product Name: Straight fluted reamer

Model name: 3102H7

Drill diameter range: 4.0mm to 20.0mm

Application: Cast iron, nodular cast iron, aluminum alloy, copper alloy

Flute type: Straight

Grade: YK10F -

Taper Shank Twist Drills

(Standard, Long, Extra Long Step Drills, Sub Land Drills and Core Drills)

Drill Standards : IS, JIS, ANSI, DIN and BS

Wide Range : Sizes from 0.30mm to 100mm (Dia) and

Length – up to 1200mmTolerances : h6 / h8 / Custom Tolerances

Material Grades used – M2, M35, M42 and ASP

-

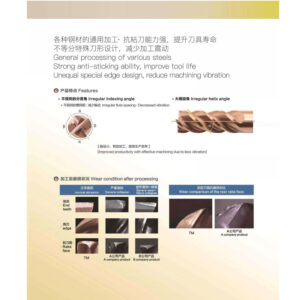

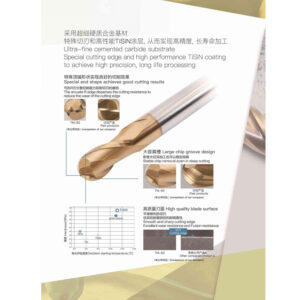

TM General Processing of Vaious Steels

- Suitable for low alloy steel, hardened steel, cast iron and other materials.

- High performance TiSiN coating, high temperature resistance, wear resistance.

- Ultra-fine cemented carbide substrate.

- Special angle design and high edge strength ensures versatility.

-

TM550 General Machining End Mill

- Suitable for processing ordinary steel and cast iron materials.

- High performance TiSiN coating.

- High temperature resistance and high wear resistance.

- Ultra-fine grained carbide material.

- Improve cutting edge wear resistance and tool rigidity.

-

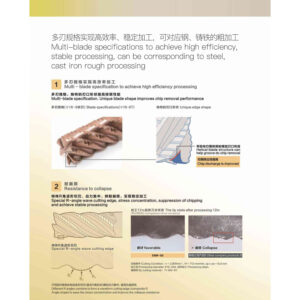

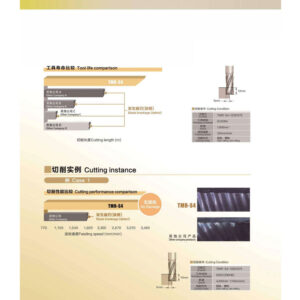

TMR Endmills for Roughing Application

- Suitable for roughing normal steel & cast iron, special chip breaker cutting edge for Groove and side machining, Altin coating.

- Improve cutting edge wear resistance and tool rigidity.

-

-

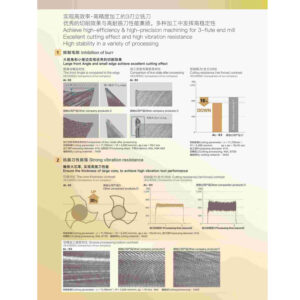

XM Ultra-high Hardness & High Efficiency End Mill Series

- Variable bottom edges and helix angles to reduce vibration and improve the surface Finish.

- The special tool design is suitable for high hardness steels processing.

- High hardness and toughness substrate.