-

(Jobber, Long, Extra Long, Stub, Step Drills, Sub Land Drills and Core Drills)

Parallel Shank Twist Drills

-

(Standard, Long, Extra Long Step Drills, Sub Land Drills and Core Drills)

Drill Standards : IS, JIS, ANSI, DIN and BS

Wide Range : Sizes from 0.30mm to 100mm (Dia) and

Length – up to 1200mmTolerances : h6 / h8 / Custom Tolerances

Material Grades used – M2, M35, M42 and ASP

Taper Shank Twist Drills

-

-

The Twist Drill Bit is composed of handle, neck and working part. It is a tool for drilling round holes in a work piece by rotating it against a fixed axis.

Twist Drill Bit

-

Product Name: Straight fluted drill

Model name: PC series (straight flute drill)

Drill diameter range: 4.0 mm to 20.0mm

Grade: YK20F

Application: Cast iron, Al alloy

Trade term: VariousStraight Fluted Drill

-

Product Name: Deep hole drill bits

Model name: SL series deep-hole drill

Drill diameter range: 3mm to 20mm

Material: Tungsten carbide

Application: Deep-hole machining

Grade: CoatedDeep Hole Drill Bits

-

Product Name: Solid carbide drill

Model name: 1101SC05

Drill diameter range: 2mm to 16mm

Application: Various

Cooling: External-coolant

Grade: YK20FSolid Carbide Drill

-

Product Name: Tungsten carbide drills

Model name: 1588SL series deep hole twist drills

Drill diameter range: 3.0 to 20.0mm

Application: Carbon steel, alloy steel, Nodular cast iron

Cooling: Internal

Grade: KDG303Tungsten Carbide Drills

-

Product Name: Carbide drill bits

Model name: SC series twist drill

Drill diameter range: 2.0 to 16.0mm

Applicable industries: Aerospace, automotive, mould, and others

Certificate: ISO standard

Ports: ChinaportsCarbide Drill Bits

-

This Metal Drill Bit for Steel is one of the best sellers for machining of soft steel and stainless steel.

Metal Drill Bit for Steel

-

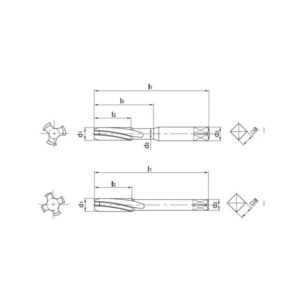

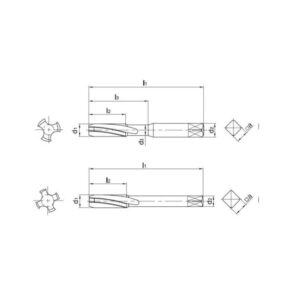

Product Name: Straight fluted reamer

Model name: 3102H7

Drill diameter range: 4.0mm to 20.0mm

Application: Cast iron, nodular cast iron, aluminum alloy, copper alloy

Flute type: Straight

Grade: YK10FStraight Flute Reamer

-

Product Name: Spiral fluted reamer

Model name: 3101H7 and 3103H7

Drill diameter range: 4.0mm to 20.0mm

Material: Tungsten carbide

Flute type: Right or Left helical flute

Brand name: ZCC·CTSpiral Flute Reamer

-

Product Name: Form tap

Model name: 4122 series of forming tap

Diameter range: M1 to M16

Type: Solid carbide

Category: Threading cutter

Place of origin: HunanChinaForm Tap

-

Product Name: Spiral flute tap

Model name: 4201 series helical-flute cutting taps

Diameter range: M3 – M16

Work piece: Cast iron, aluminum alloy

Category: Cutting tap

Brand: ZCC·CTSpiral Flute Tap

-

The Straight Flute Tap is generally used for thread machining of general lathe, drilling machine and tapping machine.

Straight Flute Tap

-

Product Name: Thread end mill

Model name: 4111 series thread end mills

Diameter range: M3 – M20

Grade: YK40F or KTG4015

Material: Solid carbide

Brand: ZCC·CTThread End Mill

-

This kind of Lathe Tool is suitable for carbon steel, alloy steel, non-ferrous metal, etc.

Lathe Tools

-

-

-

-

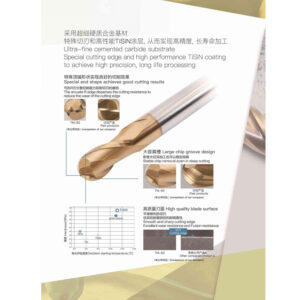

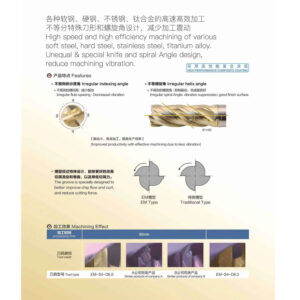

- Suitable for processing ordinary steel and cast iron materials.

- High performance TiSiN coating.

- High temperature resistance and high wear resistance.

- Ultra-fine grained carbide material.

- Improve cutting edge wear resistance and tool rigidity.

TM550 General Machining End Mill

-

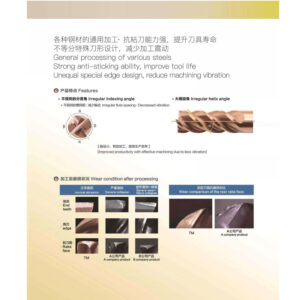

- Suitable for low alloy steel, hardened steel, cast iron and other materials.

- High performance TiSiN coating, high temperature resistance, wear resistance.

- Ultra-fine cemented carbide substrate.

- Special angle design and high edge strength ensures versatility.

TM General Processing of Vaious Steels

-

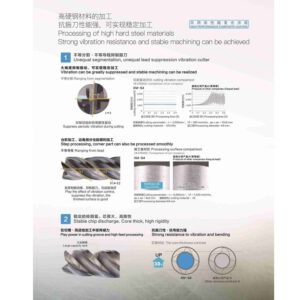

- Suitable for high hardness steel, high efficiency processing.

- Unequal spiral Angle, unequal pitch design, has excellent vibration resistance.

- Suitable for high efficiency cutting with large cutting depth and width (good rigidity of machine tool)

- Unequal helical Angle, excellent vibration resistance.

EM High Performance

-

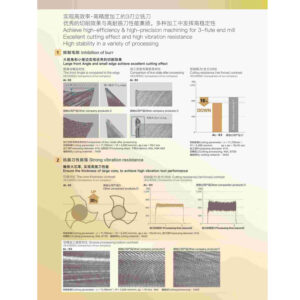

- Variable bottom edges and helix angles to reduce vibration and improve the surface Finish.

- The special tool design is suitable for high hardness steels processing.

- High hardness and toughness substrate.

XM Ultra-high Hardness & High Efficiency End Mill Series

-

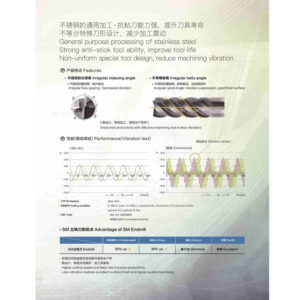

- Suitable for general processing of stainless steel.

- Special cutting edge design, Effectively solve the problem of cutting edge chip Sticking

- Stainless steel special coating, cutting smooth, anti-stick tool ability, improve tool Life.

- Unequal special knife shape, reduce vibration, high surface finish.

SM Stainless Steel General Processing End Mill

-

- Suitable for high efficient and super bright processing of aluminum alloy materials.

- Variable helix angle and differential flute pitch, reduces and eliminates vibration High precision of machine surface.

- Special edge design, Effectively solve the problem of sticking.

AL Super Bright Aluminum Processing Series

-

- Suitable for deep groove processing various steel and cast iron.

- High performance TiSiN coating for high temperature and wear resistance.

- Long neck design avoid collisions with workplace, Suitable for deep pocket milling Of mold rib.

- Fine grinding, high precise sizes.

MM Suitable for Micro Diameter Pocket Milling